The Problem: An area high school’s kitchen was shut down for a large building renovation, which meant the school was going to have to arrange for over 2000 meals a day to be prepped offsite and then delivered to the student body.

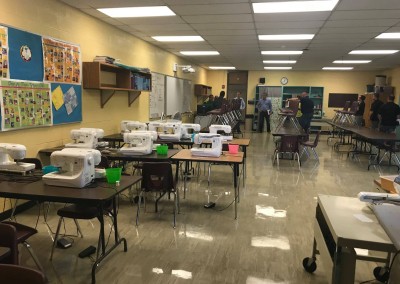

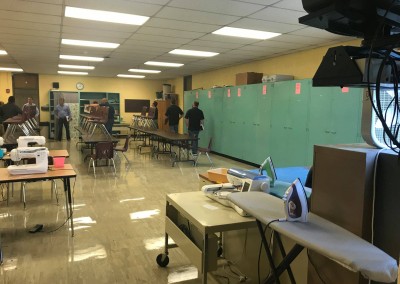

The Innovative Solution: An underutilized Home Economics room was converted into a temporary kitchen, which means the staff (of four main cooks and their support and serving teams) has been able to continue serving the students onsite, saving the school a lot of hassle and money! And don’t worry, there is an adjacent Home Ec room that is managing all of the current classes for this school year, so the students aren’t missing out on this experience!

Essential food prep equipment was relocated to this room, including a reach-in refrigerator, two double-stack convection ovens, and work tables. Additional equipment was needed to make this interim kitchen feasible, so a number of supplementary pieces were brought in: CORE exhaust hoods (with the water wash feature), prep tables with disposers, 3-compartment sink with tank heater, a 20 quart mixer, two baker’s tables, a mobile proofer/heated cabinet, expanded refrigeration on south wall, a double stack steamer, a 6-burner high efficiency range, new hand wash sinks, and seven overhead electrical cord reels.

Because this room was not originally intended to be a kitchen, several challenges did present themselves. One of these involved the hood system. Since this hood is in a school (and the students will be using it after the project is complete), it needs to properly extinguish any fire in an accelerated amount of time. This led to the CORE hood system being installed. It is not a standard ANSUL fire suppression system, but instead has a fire termination setup that incorporates the building fire sprinklers, as well as a chemical surfactant. It also has advanced fire detection, real time monitoring, total flood coverage (which is an advantage for a multi-phase project with different equipment) in lieu of appliance specific ANSUL Nozzles, and a self-cleaning system for filters, ducting, and plenum.

Another challenge facing this innovative solution required increasing the incoming water temperature. Since this interim kitchen was set up using what utilities were available in the Home Ec room, the water temperature did not meet the health code. The three-compartment sink sanitizing bay was only able to get to 120 degree temperatures, which is 20 degrees too low. During the design phase, we specified a tank heater specifically for the last bowl in the sink to reach the mandatory requirements.

Fun Fact Regarding this Innovative Solution: This room is also part of a long-term project to provide the students with a culinary kitchen! This should be complete in time for the 2018-19 school year, with the process of converting the production kitchen into a culinary arts room expected to last from June 4th to August 2nd.

Learn more about how Rapids can help you by exploring our other projects!

LET’S FIND YOUR SOLUTION

Rapids Contract serves the United States with locations in Iowa, Minnesota, and Missouri!

Get in touch with one of our experts and let us know how we can help with any of your foodservice needs.

Talk to one of our experts right away and get immediate assistance. We are open Mon – Fri, 8am – 5pm CST.

Get in touch with one of our experts and let us know how we can help with any of your foodservice needs.

Talk to one of our experts right away and get immediate assistance. We are open Mon – Fri, 8am – 5pm CST.