The Problem: When evaluating capital equipment purchases, how can I evaluate the long-term cost of ownership as it relates to repair, maintenance and energy consumption? Do certain brands offer a better return on investment and fewer refrigeration failures?

The Answer: Since all brands of refrigeration are engineered and developed differently, the long-term cost of ownership must be evaluated on several fronts:

- How much energy is consumed?

- How frequently will the new unit fail?

- How much will it cost me to repair the unit when it fails?

- How frequently will scheduled maintenance be performed on the unit?

Unfortunately, not all of this information is readily available for public consumption. Energy consumption is the most accessible data point, but doesn’t provide enough information by itself.

Chain Restaurant Solutions, a Rapids affiliate, has been tracking data for over 10 years on equipment placed in various operations and markets, working in an array of operating conditions.

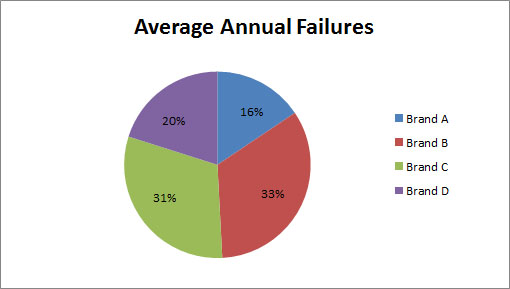

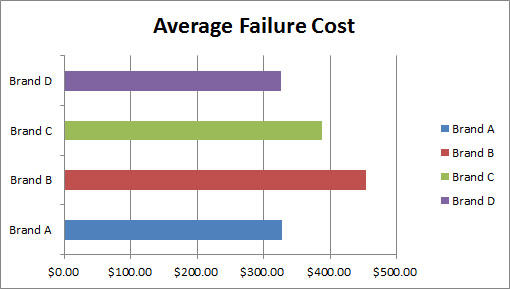

Our data focused on refrigeration failures in four of the major commercial refrigeration brands, and tells us that over the first 10 years of a self-contained refrigeration unit’s lifespan, the average failure rate per year was 32.7%. This means that, on average, almost 33 of 100 units will experience some sort of failure each year for the first 10 years of life. In addition, we found that the average cost of a repair is $374.

One of the main components affecting the refrigeration failures rate variance and average repair cost is brand.

| Avg Units | Avg Annual Failures | Avg Failure Cost | |

|---|---|---|---|

| Brand A | 396 | 20.40% | $327.31 |

| Brand B | 285 | 43.90% | $454.60 |

| Brand C | 329 | 40.20% | $387.96 |

| Brand D | 1092 | 26.30% | $326.74 |

| Total/Average | 2102 | 32.70% | $374 |

The units included in this analysis are spread across primarily fast casual and QSR operations across the United States.

While these results are not 100% inclusive by any means, the variance in the failure rates of the units in our data set seems to indicate clearly that making an informed decision at the time of purchase can have a significant impact on the return on investment experienced by the equipment’s owner.

A 100-outlet operation may have 600 pieces of such equipment in their stores at any point in time, and depending on the brand choice, the R&M spend could vary from approximately $40,000 to $120,000 over the 10-year period.

If you assume an average cost of $2,000 for a new unit, you could have replaced 20-60 units in that timeframe instead.

When you choose to work with Rapids Contract & Design, we will use this data to help you find refrigeration equipment that offers the best return-on-investment option for your business and budget. Contact us today!

LET’S FIND YOUR SOLUTION

Rapids Contract serves the United States with locations in Iowa, Minnesota, and Missouri!

Get in touch with one of our experts and let us know how we can help with any of your foodservice needs.

Talk to one of our experts right away and get immediate assistance. We are open Mon – Fri, 8am – 5pm CST.

Get in touch with one of our experts and let us know how we can help with any of your foodservice needs.

Talk to one of our experts right away and get immediate assistance. We are open Mon – Fri, 8am – 5pm CST.